Electromagnetic Compatibility – Design for EMC

Our experience dealing with electromagnetic compatibility (EMC) from both a design and final lab testing perspective give us the know-how to make a product development bulletproof to electromagnetic effects that may impede design performance during real world use. By ensuring a design has the correct hardware elements and software design to protect against EMC effects, this will result in a significantly more reliable product which will not only sail through EMC compliance testing, but will also have a superior performance and reliability compared to designs where this is not properly considered. Whilst there are may elements to consider, the main issues we focus on include:

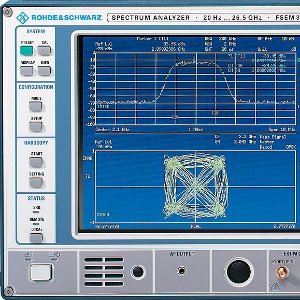

- Quick desk based evaluation – required design compliance to applicable EMC standards such as generic, radio, ITE, etc. coupled with hands-on bench based design analysis or test. Also simulation of EMC performance of completed circuitry and PCBs.

- Inclusion of active and passive components – within the hardware to protect against EMC, such as surge protection, diode suppressors, gas discharge tubes and ferrites.

- Circuit and PCB level segregation – planning against noise and disturbances.

- Defensive software code against undefined behaviour such as lockstep design and checksums/integrity checks.

- Initial Radio Emissions & Susceptibility tests – identification of victim and aggressor traces on PCBs to indicate sources of trouble which may interfere with sensitive devices such as mobile phones or audio equipment during normal operation or may be susceptible to interference from it’s environment.

- Initial Conducted Emissions & Susceptibility tests – such as ESD, transient, spike/surge, fast transients and how the PCB and circuitry handles this.

- Focus on EMC hotspots – such as switched mode power supplies (SMPS), un-slewed high speed digital circuitry etc.

- Signal Integrity design aspects – such as transmission lines, differential signalling, filtering and line terminations.

- Specialist EMC Support – support for specialist EMC testing such as aerospace/defence including MIL-STD-461 and DEFSTAN 59-411

Whilst many designers usually leave most of the above activities to the final stages of design, we prefer to be proactive and address these issues at the earliest possible point of a design where cost of remedial work is lowest, as EMC related costs of mitigation are generally exponential as the development progresses.